quickturn PCB services affected by design errors

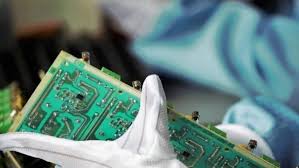

The demand for quick turn PCB services has been on the rise due to the increasing need for electronic and electromechanical products for a variety of industries. While leveraging this service type can be beneficial for OEMs looking to stay ahead of market trends, it also poses challenges that can be difficult to overcome without the right experience and knowledge. The key is balancing speed with quality, and in this article, we’ll discuss how this is achieved through advanced inspection techniques, efficient testing protocols, and a dedication to customer satisfaction.

Fortunately, many quickturn pcb manufacturers have dedicated teams that work all day and night to ensure high-quality results are delivered to customers within their promised turnaround time. This is especially true of those that are experienced in working with a diverse range of industries and applications. Choosing the right quick-turn PCB manufacturer for your needs starts with evaluating their client base and their history of delivering on their promises.

It is also important to choose a manufacturer with an extensive network of vendors, which can help with both the procurement process and the delivery timelines. This will minimize any delays or complications that might occur as they try to source necessary components. Additionally, a knowledgeable and experienced manufacturer will be familiar with different design requirements and manufacturing processes, which can help them avoid costly errors that may be caused by lack of familiarity.

How are quickturn PCB services affected by design errors?

Mistakes in PCB design are common and can often be caused by a number of factors. A lack of understanding of the fabrication process, for example, can lead to dimensional tolerances that are outside what is required for manufacturing and increase costs or complexity. In some cases, it can even change the footprint of the finished circuit board. Similarly, inexperienced designers can miss critical elements like the placement of thermals or the use of an incorrect pinout. Even the most seasoned designers can make a mistake, however, and it is always best to have a second pair of eyes review a project before it is sent off for fabrication.

In short, avoiding mistakes in a design can save a great deal of time and money. Creating a template that all designers have access to can reduce the number of times changes are made and provide a level of consistency that can help catch errors before they are made. Peer reviews can also be very helpful in catching design errors that might otherwise go unnoticed.

In addition to the tips above, a reputable and knowledgeable PCB assembly service will have an extensive and diversified production capacity. This allows them to meet the needs of a wide range of clients, while still being able to deliver on their promised turnaround times. Inquire about the manufacturer’s equipment and production capabilities to see if they can match your needs. Ask about their SMT lines, AOI systems, and other cutting-edge technology that can streamline production and improve quality. Ultimately, finding the best quality and value in quick-turn PCB production comes down to choosing the right manufacturer for your needs.