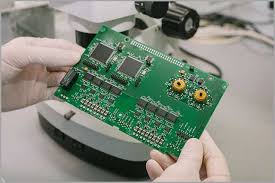

Printed Circuit Board Assembly

A printed circuit board (PCB) is a conductive pathway that supports electronic components and electrical wires by connecting them to the chassis of the device in which they’re being used. PCBs are an essential component of most electronic devices, and their use is widespread across a range of industries. However, the PCB manufacturing and assembly process can be complex, and it’s vital that manufacturers adhere to established industry norms to ensure a high-quality final product.

While many people think that a PCB and a PCBA are the same thing, they’re actually two different steps in the overall process of creating an electronic circuit. A PCB is a blank circuitry board that does not have any electronic components attached, while a PCBA is a fully functional circuitry board that contains all of the required components for its intended application.

The process of manufacturing a PCB starts with printing the desired circuitry design onto a piece of copper-clad laminate using a photographic method. Once the copper-clad laminate is printed with the circuitry design, it must be etched to remove the exposed areas of the copper and leave behind the desired conductive pathways. This step requires careful planning to ensure that the etching process does not damage any of the other components.

After the etching process is complete, it is time to drill holes into the circuit board where the electronic components will be inserted. These holes are known as vias, and they must be drilled with great precision to ensure that the component leads have a snug fit. The vias are then plated with copper in order to strengthen them and prevent corrosion. Finally, the remaining exposed copper is cleaned by a chemical process and polished before being soldered in place.

What Is a Printed Circuit Board Assembly?

Adding the individual electronic components to the PCB is a labor-intensive process that can be performed by hand for smaller projects or by machine for larger ones. Once the component placement is complete, the assembly must be soldered in place using either a wave soldering machine or a reflow oven. Both methods have their advantages and disadvantages, but they both require skilled human intervention and a high-quality finish to produce a robust and durable circuitry assembly.

It is crucial for manufacturers to prioritize compliance with established industry norms and regulations as an integral part of their operational ethos. This ensures that the finished product meets rigorous performance criteria and avoids any potential safety hazards or environmental concerns. Additionally, it demonstrates a commitment to quality and reliability that is sure to build trust with consumers and regulatory bodies.

As technology continues to advance, it is likely that the industry will continue to see a proliferation of innovations that enhance efficiency, precision, and quality in the manufacturing and assembly processes associated with printed circuit board and assembly. These technological trends offer the potential for heightened operational efficiencies and more reliable products that can be trusted to work effectively in any setting. They also reinforce a commitment to sustainable manufacturing practices.